Centravis has developed the production process for TP316L UG (Urea Grade)

CENTRAVIS has successfully completed the development of cold finished tubes TP316L UG (Urea Grade).

CENTRAVIS has successfully completed the development of cold finished tubes TP316L UG (Urea Grade).

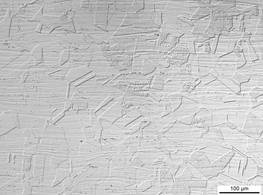

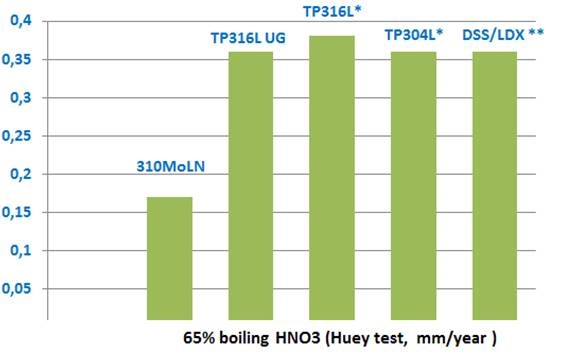

The developed technology allows us to guarantee the corrosion resistance for cold finished tubes and pipes of TP316L UG (Urea Grade) in 65% nitric acid with a minimum weight loss during exploitation of the finished product thanks to the sustainable austenitic microstructure even at extreme high concentrations of acids.

“TP316L UG (Urea Grade) has designed and approved by the major engineering companies and intended to be used in the chemical industry where the material requires the improved corrosion resistance to nitric acid. Development of technology and inclusion of this steel grade in our product catalogue, of course, is an excellent chance for our Company to take part in major and important projects in the chemical industry segment” – comments Andrey Balev, the Head of R&D.

In addition to implementation of TP316L UG (Urea Grade), it has been planned to complete by the end of the 3rd quarter of 2019 the development of the heat treatment technology for tubes grades made of standard billets. The designed technology is intended to guarantee a corrosion rate at the level of more alloyed and more expensive alloys and steels.

Corrosion Rate in boiling HNO3, ASTM A 262, pr. C (Typical values)

* After an advanced heat treatment; corrosion rate for grade TP304L in sensitized condition.

** Duplex (S31803/32205) and Lean Duplex (S32304).

Material diversification is a great opportunity for a potential customer and will allow CENTRAVIS to increase its competitive advantages and ramp up its sales in the chemical industry sector.