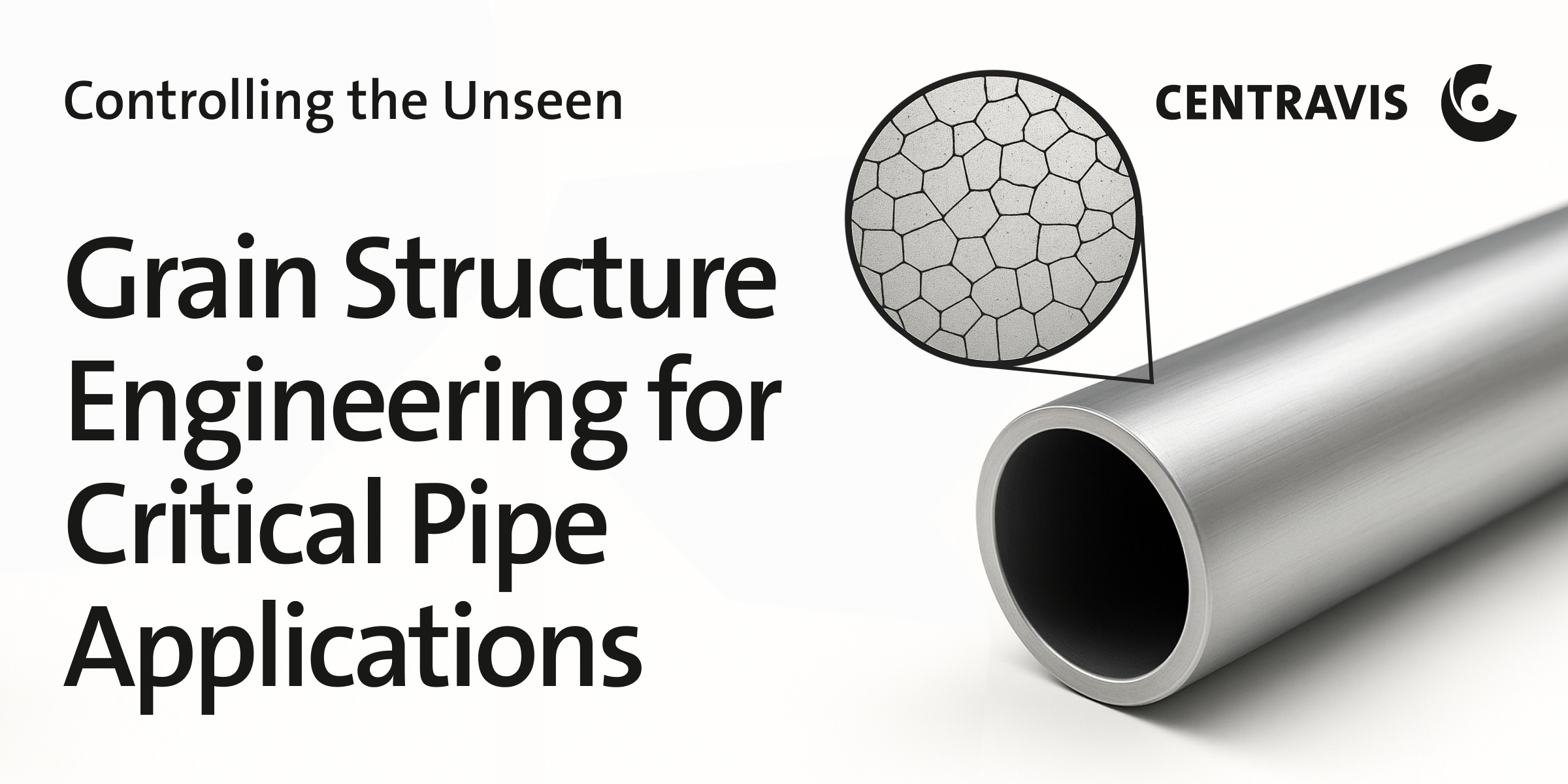

In modern pipe manufacturing for critical industries — including energy, chemical processing, oil and gas, and aerospace — control of the material’s grain structure is a crucial factor for ensuring the reliability and longevity of the pipes. Although grain structure is invisible to the naked eye, its influence on the physical and mechanical properties of the material is extremely significant. How engineers control the behavior of grain boundaries affects not only the strength of the pipes but also their resistance to corrosion, fatigue, and deformation during long-term service.

This article discusses thermomechanical and heat treatment processes and their impact on grain boundary behavior. We also examine how the microstructure of the material determines the long-term durability of pipes under cyclic loads and corrosive environments.

How Thermomechanical and Heat Treatment Affect Grain Boundary Behavior

Thermomechanical and heat treatment processes are the primary methods influencing the formation of steel’s grain structure. They allow for precise control of grain size, distribution, and grain boundary characteristics, which in turn determine the mechanical properties of the material.

Thermomechanical processing involves procedures in which temperature and mechanical load are applied simultaneously, including rolling, extrusion, and forging. These methods enable the achievement of the desired grain structure by controlling temperature and deformation rate. Reducing grain size in this way improves material strength, enhances fatigue resistance, and increases the longevity of pipes used in critical infrastructure.

Heat treatment — including annealing and quenching — is used to regulate the mechanical properties of the material, particularly strength and ductility. These methods allow modification of grain size and stabilization of grain boundaries. A critical part of heat treatment is controlling the cooling rate after heating, as this affects whether grains grow or shrink in size.

Through these processes, a more uniform structure with minimal defects at grain boundaries can be achieved, positively influencing the overall mechanical properties of the pipe.

The Influence of Microstructure on Longevity, Fatigue, and Corrosion Resistance

Grain structure significantly impacts three main characteristics of pipes: fatigue resistance, corrosion resistance, and long-term resistance to deformation. The grain structure can be a determining factor for the service life of pipes in critical conditions.

Fatigue Resistance

Pipes operating under cyclic loading conditions (e.g., fluctuating thermal environments) must withstand numerous cycles of tension and compression. A fine-grained microstructure greatly improves fatigue resistance because smaller grains reduce stress concentration at grain boundaries, where microcracks frequently form and can eventually lead to pipe failure.

Corrosion Resistance

In many critical industries, such as oil and gas and chemical processing, pipes are exposed to aggressive environments where corrosion is a leading cause of failure. The smaller the grain size and the more uniform the structure, the higher the corrosion resistance, as corrosive elements like chlorides are less likely to penetrate weak points along grain boundaries.

High-Temperature Creep Resistance

Elevated temperatures, often encountered in service, can lead to creep — the slow deformation of the material under sustained load. Fine-grained structures enhance material resistance to creep, as these grains provide better resistance to displacement under high temperatures.

Why Fine-Grained Austenitic Steels Excel in Cyclic Thermal Conditions

Due to their microstructure, fine-grained austenitic steels are ideal for pipes operating under variable temperature conditions. Austenitic steels are capable of plastic deformation and have high corrosion resistance, but in high-temperature and cyclic stress conditions, their performance can be significantly improved by achieving a fine-grained structure.

Enhanced Resistance to Thermal Cycling

Austenitic steels with fine grain structures handle thermal cyclic loads more effectively, as smaller grains reduce the degree of thermal fatigue in the material. This is especially critical for heat exchangers and pipes used in energy facilities, where temperature changes rapidly and repeatedly.

Improved Ductility and Strength

Fine-grained austenitic steels exhibit high ductility and tensile strength, making them ideal for applications where pipes must withstand substantial thermal and mechanical loads.

Visual Case Examples Using EBSD and Microscopy

Modern analysis methods, including Electron Backscatter Diffraction (EBSD) and traditional microscopy, are used to study grain structure and its impact on pipe performance.

EBSD

EBSD provides detailed information about grain orientation, boundaries, and the phase structure of the material. This allows engineers to determine how different types of grain boundaries affect mechanical properties, including strength and fatigue resistance. Microstructure analysis via EBSD enables the development of materials with optimal properties for high-temperature and high-pressure applications.

Microscopy

Conventional microscopy allows for detailed examination of the material structure and detection of defects at grain boundaries, such as cracks or inclusions, which could reduce pipe longevity. This enables engineers to optimize production processes and minimize the risk of defects in the final products.

Conclusion

Grain structure control is critically important for pipes operating under high temperatures and cyclic loading conditions. Fine-grained steels provide high resistance to fatigue, corrosion, and creep, making them ideal for applications in critical industries such as energy and chemical processing. By employing thermomechanical and heat treatment processes, as well as modern analytical techniques like EBSD, the microstructure of the material can be precisely tailored to achieve optimal performance.

Grain structure engineering allows for high reliability of pipes and ensures their effective operation under extreme conditions, which is vital for the safety and longevity of technical systems.