Yuriy Atanasov, Co-owner of Centravis (Photo by: Centravis)

Yuriy Atanasov, Centravis CEO and Co-owner, told ‘NV Business’ about the prospects for the electric vehicle market, the need for trade with Russia, and why the headquarters of the global company is located in Nikopol.

Centravis is a family-owned company established in Nikopol (Dnepropetrovsk region) on the basis of two workshops of the Nikopol South Pipe Plant – a behemoth of the Soviet pipe industry, which in the 1990s split into several independent legal entities. Until 2007, Centravis was known as UVIS. The abbreviation was made by the first letters of its owners’ names: Vasily Atanasov, his sons, Yuriy and Sergey, and Vasily Atanasov’s wife, Irina.

Today, the company is run by Yuriy Atanasov, and his son is among the top management. That is, the third generation of businessmen from the Dnipropetrovsk region has already been running an industrial enterprise. This is rather rare for Ukraine.

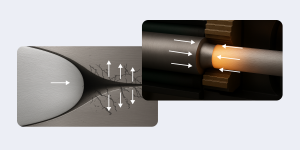

Even more interesting is the fact that Centravis is one of the world’s largest manufacturers of seamless stainless steel pipes. Products manufactured in Nikopol can be found in almost all German cars with internal combustion engines (ICE). For many years, the company has been a key supplier of tubes for BMW and Volkswagen fuel systems. We sell in the USA as well. We have recently started commercial supplies for the car industry in Japan. At the beginning of the year, the company’s management spoke about its first contract with Usui Co., a Japanese manufacturer of components for automotive fuel systems.

Today, Centravis is world 2nd supplier of pipes for internal combustion engines. These products account for about 20% in the enterprise portfolio. At the same time, the headquarters of the company, which exports over 95% of its products, is located not just in Nikopol, but directly in the territory where production workshops are located. Even expatiate top managers have to move to this industrial city, located 120 kilometers from the regional center.

‘NV Business’ spoke with Yuriy Atanasov, CEO and co-owner of the company, about the specific features when developing a family business, the experience of cooperation with the EBRD, and the risks of transition of global automakers to electric vehicles.

Centravis Products/ Photo by: Centravis

Centravis Products/ Photo by: Centravis

Experience with EBRD, 6 salaries at redundancy, and radio-controlled cranes

— What are Centravis’ production and financial results in 2020?

— We ended the year with small losses in volume. We produced and shipped about 19 thousand tons of pipe products with EBITDA of about EUR 16 mln. This is about twice as good as in 2019. One of the factors that helped us is the hryvnia devaluation.

— What are your plans for 2021?

— We are estimating about 10% less volume. At the same time, the demand for our products has fully recovered, and we can stop losing in volumes. However, we want to increase labour productivity without restoring the number of personnel. We had to cut 25% of our staff by the end of the last summer.

— How many people was that?

— About 400 people. We have 1,400 employees now. We held off until we could, worked in partial load mode, put people on leaves and tried to retain the personnel in every possible way. We didn’t manage to do that because the crisis especially affected us in the summer. A significant part of our products is manufactured for the car industry. So when this industry stopped all over the world, we had to reduce the personnel. The market also recovered sharply at the end of the last year and the auto industry started up.

— I heard that you are giving up some professions due to automation. For example, crane operators.

— Yes, this is one of the elements. You can imagine: there are 50 cranes in the company. If there are four shifts, then there are 200 of only crane operators. We already have entire units where processes allow switching to remote control. Cranes are equipped with radio control and the remote control is operated by the operator on the ground. We are moving towards this, but we still have crane operators.

— Have these processes accelerated in your company due to the coronavirus crisis?

— Not really. Because we were afraid to spend money last year. Our task was to retain liquidity. We did not understand the scale of the crisis and how seriously it would affect us in terms of orders and liquidity. The uncertainty was vert high. We have spent only up to EUR 2 mln on investments.

— What are your plans in terms of financial performance?

— The minimum target is to retain operating profit at the same level. But now we see opportunities to raise it by improving efficiency and working with the market and, possibly, by recovering prices.

— What period have you received orders for as for now?

— Almost until the end of the year. There was a real boom from December to March. Now, we offer production dates at the end of this year — the beginning of the next year for individual segments of our product range.

— How has the coronavirus crisis affected the operation of the enterprise in general?

— This year taught me that a company can be saved or supported by two things in such crisis situations. The first is strong partnership relations with clients, because you won’t get new clients in such a situation. And those you have worked with for decades will not experiment. The second is our employees. It is sad and painful for me to say that we had to cut our staff, but when doing so, we offered a severance pay significantly higher than that provided for by the law: up to six salaries.

— But this shows that Ukrainian industrial enterprises are still hostages of the redundant personnel as was established in Soviet times.

— You are partly right that we have a certain “layer” of inefficiency in the form of redundant personnel. But the opening of labour markets in Poland, the Czech Republic and other European countries, in my opinion, has a healthy impact on Ukrainian business as it demands from Ukrainian entrepreneurs to improve their work efficiency. How did they think before? 100 people are waiting to get a job at your enterprise. So why invest in a radio-controlled crane or an automatic line? It’s expensive, don’t buy it! Now we – entrepreneurs and employers – are more and more moving towards real market conditions when we compete for qualified personnel who want to work safely, efficiently and autonomously. And we have to pay them good money.

— What is the level of wages at the enterprise for blue-collar jobs?

— The average wage before taxes tends to UAH 20 thousand.

— The European Bank for Reconstruction and Development (EBRD) was your shareholder for some time. What did this give Centravis in the end?

— It was huge experience both for me personally as a manager and for the company as a whole. Firstly, it was the construction of corporate governance, when a private company has an independent board of directors and is accountable. Accountability is the key word here. In family companies it is often like: someone came, someone didn’t come, we decided this or that… And this also affects management, corporate culture. It is very disciplining when everything is strict, when there is an independent board of directors and there are observers of a minority shareholder. It develops the ability to clearly formulate and justify your decisions as well as to give reasons for them, and make it concisely. You can’t talk a lot and emotionally. I remember how my attitude to this changed: we have grown it all here since 1993, what can you understand there in London? But all this ultimately comes to a common denominator: you must justify, show and implement.

They also taught that there is always an opportunity to justify certain deviations. It is not obvious that they will be accepted, but you will always be listened to and your arguments will be accepted, assessed and supported.

— Did you buy out their share?

— At the end of 2018, we restructured the debt, paid it off with a markdown, and then we bought out the EBRD’s share with a premium.

Stainless Pipe Processing at Centravis / Photo by: Centravis

Stainless Pipe Processing at Centravis / Photo by: Centravis

Electric vehicles, duties and Zaporozhye metal

— I interviewed the Centravis’ Marketing Director several years ago. He then said that it had been a long time since the company had started the sales diversification process in order to reduce dependence on a single market…

— I would like to say that we are so smart and knew everything in advance. But 20 years ago, dependence on a single market was natural. After all, the plant was built as part of the Soviet Union and worked for the USSR. But specifically the Russian Federation market started to push us out due to quotas and duties in the early 2000s. I really mean “pushing out”. This began to happen regularly and steadily even 15 years before the conflict (with the Russian Federation in Crimea and Donbass — ‘NV Business’). And we found ourselves facing a choice: either we would shrink to the level of a local supplier for a very small Ukrainian market, or we needed to actively diversify. But this takes a very long time. If this happened in 2014, our company would not have survived.

— Did you have practically no support from the domestic market?

— Today, we sell less than 5% in Ukraine. We are a unique company in our segment in this sense as all competitors have a domestic market: some have 30% of it, others have 50%.

Therefore, we had to not only develop our client base. We made investments in order to provide a product and service that will be in demand and competitive in Western markets.

— How long does it take to fill a niche in the stainless pipe market?

— We started trying to manufacture and supply the first samples of tubes for the German car industry about 12-15 years ago. It took several years and dozens of inspections of engine components manufacturing sites and end customers before we started pilot and then serial deliveries. We have been reaching the current volumes for this segment for seven or eight years. We are now second in the world after the Swedish company Sandvik.

— What is the share of the car market in your portfolio now?

— About 20%. There is a good margin, above the average in terms of our supplies.

— Do you see a risk for yourself in the transition of the global car industry to the production of electric vehicles?

— There is such a trend. We estimate that no more than 10 years is left. Estimates show that this trend will not be very sharp in replacing one type of engine with another. But our R&D focuses on improving the consumer properties of our products so that we can successfully compete in other segments. Such as aviation or space industry.

— What other industries besides the car industry do you supply with your products now?

— Historically, we worked for the nuclear energy of the Soviet Union, and now we are working more and more for the nuclear industry in Europe. For example, we supply pipes for a nuclear power plant under construction in England.

Our large customers also include the representatives of thermal power industry, a lot of chemistry and petrochemistry enterprises. Have you ever been to Viena?

— No, I haven’t.

— If you are driving from Vienna airport towards the city center, you pass the OMV chain of refineries. There is a lot of stainless steel. These are all our pipes that are used for cracking. Such German concerns as BASF and Linde are also our clients.

— Do you work with the Russian Federation now?

— The diversification trend has been established long time ago… And it has organically continued in recent years. The share of sales to Russian companies has currently dropped to 10% of the total volume. 20 years ago it was 80%.

— Do you still have to work with them?

— We work in the segment where other Ukrainian companies also cooperate with them. The supply of nuclear fuel to Ukrainian nuclear power plants can be an example. Our pipe deliveries are, to some extent, an element of cooperation in the nuclear power segment (of two countries – ‘NV Business’).

— You have already mentioned protectionism. Ukrainian metallurgy today is regularly faced with safeguard investigation. Are there duties and quotas in your segment? How does this affect Centravis?

— Very strongly. This is always the focus of our radars. If we see attempts to carry out investigations or to prepare defensive duties in a particular market, we immediately join. There is a quota in Europe and a 25% duty in the USA.

— By the way, there are some exceptions for your products in the USA…

— Right, but this is so much work! We only have two sellers in Houston. They probably spend half of their time not to work with clients, but to preparing new applications to the regulatory authorities to get some products released from the duty. But the procedure is just awful. An application must be submitted separately for each schedule size. For 50 tons, for 100 tons. And you have to do that over and over again.

— More than half of your raw materials is from the Dneprospetsstal plant (Zaporozhye). Do they meet your quality requirements?

— It is very convenient for us to work with a supplier who is just 100 kilometers away. Dneprospetsstal is very flexible in supplies. If we place an order for May at the end of April, then during the first 5-10 days of May we can correct part of it in the gauge. This is unique! It allows us to significantly reduce our stocks.

— But this is also a risk for you, isn’t it?

— How do we manage risks? We will always buy a certain share of the portfolio not from them. It could be India or Europe. We buy a complex range like nickel alloys from Italy and Germany.

— Is it comparable to Zaporozhye in terms of price, excluding logistics?

— It is more profitable in Europe, because they have more modern technology for complex steels. Dneprospetsstal is in dire need of upgrading its capacities.

Stainless Pipes Manufacture at Centravis / Photo by: Centravis

Stainless Pipes Manufacture at Centravis / Photo by: Centravis

Features of corporate culture

— Your company’s headquarters and production are located in Nikopol. I talked with a person who was interviewed for a management position, but there was a condition to «move to Nikopol». He had to refuse. Don’t you think that in this way you restrict your possibilities of hiring qualified management?

— It is better to have an average but motivated and working in a team management in Nikopol, at the production site, than high-quality management out of touch with production.

— But I myself am from Mariupol, and I understand that Nikopol, as a city, certainly does not provide its residents with many opportunities for leisure. Or do your top managers, who include expats, fly away for the weekend, let’s say, to Vienna and return to the production site on Monday?

— We don’t have people who fly to Vienna, Frankfurt or Paris every weekend. There are several people who go to Kiev for the weekend. This is maximum. In other respects, all those who work here…

— Are dedicated to production?

— The word “production” is too loud. But they understand and accept the importance of being here, where the value is created. We are building a unique company and a unique culture. And our production is the core of this culture. You can only be outside of it if you are closer to the client.

We moved to Nikopol from Dnipro in 2007. And only in 2016, nine years later, we realized that we had not finished the moving. We have first moved to the central office of the former plant management. And in 2016, we moved directly to the plant site.

— You have a family company. But what are your plans for the future? I saw your website, there is Artiom Atanasov among the top management.

— He is my son.

— Are you planning to involve the younger generation in management more actively or are you thinking of attracting professional managers?

— We encourage family representatives’ work in the company. But we do not force the hand. On the other hand, it is not a special privilege. You have to earn it or to pass the competition in order to get this or that position in the management.

— Perhaps you are planning to merge with someone or sell the company, aren’t you?

— Any book on investment says that a company should be sold at its peak. We know how to increase this cost. Above all, by further improving our efficiency. It motivates us. So we have other things to worry about except for sale. On the other hand, like any family company, we are quite conservative, and we hold on to this business because the family is already associated with it. This has its drawbacks as you can miss the moment when the company is on peak of its value. We have an independent board of directors for this that monitors the development of the company, its strategy, periodically asks us, the management: “What are our future prospects?”

— You had a very high creditor burden several years ago, but you reduced it intentionally. Why did it happen? And by what finance are you going to upgrade the production?

— Before the 2008 crisis, we actively borrowed money and invested it in renovation. It was then that the foundation was laid for the successful development of Western markets. We invested about $ 150 mln. And the total loan portfolio by 2010, when the crisis already hit, reached $ 140 mln. We have lived with this debt burden for nearly 10 years. $ 10-12 mln was spent annually only to pay bank fees. At the same time, some local crises always hit different markets. It was like a situation where a wall is falling, and you are trying to escape from it. You run, and the shadow catches up with you. You understand that the shadow is getting longer and longer. And you do not understand whether you manage to run away from the place where the wall will fall and cover you. Therefore, we have a feeling now that we are in complete control of the situation and liquidity. It’s so amazing! This is the feeling that we definitely do not want to lose.

— What is your current debt load?

— Net debt, taking into account the cash in bank, is less than EUR 30 mln.

We have already completely cleared our loan portfolio. It is absolutely sound, manageable, and we will continue to keep it under control. And we will finance projects out of our profit.