In stainless steel tube manufacturing, material integrity remains a primary focus for engineers, metallurgists, and quality control specialists. Seamless tubes, used in critical applications from energy to aerospace, must meet strict requirements for dimensional precision, mechanical reliability, and corrosion resistance. The method of tube formation plays a decisive role in shaping these properties. Among the most common techniques, piercing and extrusion each offer distinct paths to achieving a seamless structure. However, they also introduce unique material characteristics, risks, and limitations. This article explores how each process affects final tube quality and guides professionals in selecting the most suitable method for performance-critical applications.

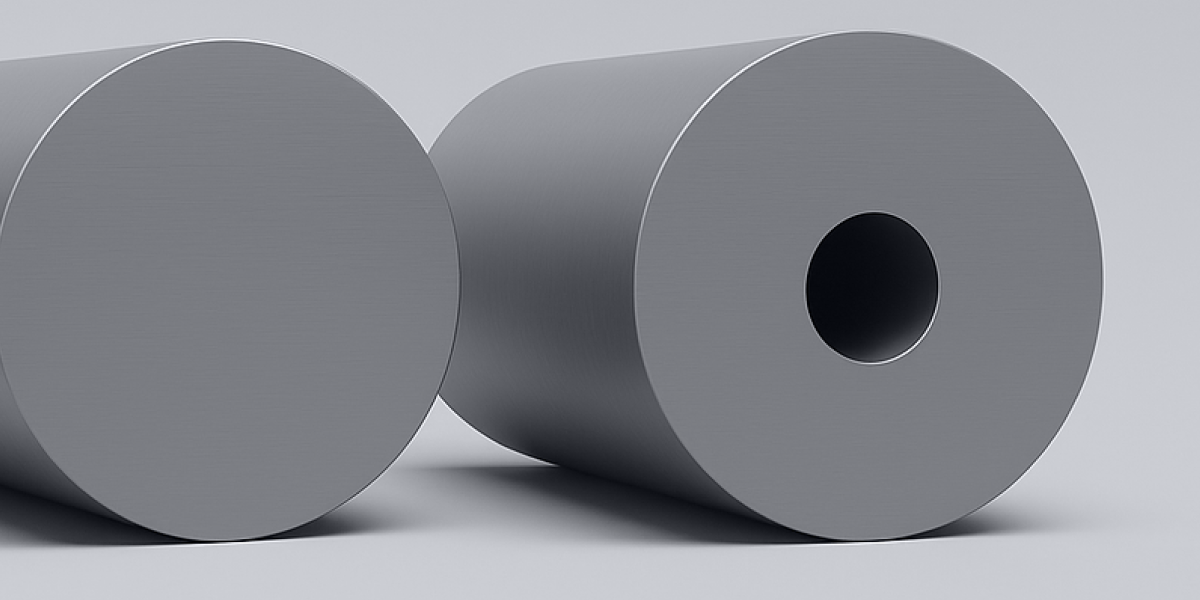

Billet Core Influence on ID Integrity

One of the most significant differences between piercing and extrusion lies in how they manage the billet’s core — the central area of the steel where non-metallic inclusions, shrinkage cavities, and segregations are most likely to concentrate.

Piercing utilizes the full cross-section of the billet, transforming it into a hollow form by using a piercing plug and skewed rolls. As a result, the tube’s inner diameter (ID) is formed directly from the billet’s core. This method preserves any internal casting defects, including porosity and inclusions, which can compromise the ID quality. These flaws may not always be visible on the surface but can emerge as performance issues under high-pressure or corrosive conditions.

In contrast, the extrusion process involves the removal of the billet core through deep drilling before hot deformation. This preemptive step physically eliminates the most defect-prone zone. As a result, the inner surface of the extruded tube benefits from higher structural integrity, with significantly reduced risk of embedded flaws. Extrusion is often the preferred method when ID purity is critical, such as in high-purity chemical processing or instrumentation tubing.

Surface Finish and Defect Propensity

Surface quality is another major consideration that differs between the two forming techniques. Piercing, operating at high temperatures and often with minimal lubrication, can generate surface issues due to friction and oxidation. Without a protective interface, the steel surface is prone to scale formation, micro-scratching, or oxide entrapment. These defects not only impact appearance but also reduce corrosion resistance and increase the likelihood of mechanical failure during subsequent processing steps.

On the other hand, extrusion typically employs synthetic or glass-based lubricants that provide a uniform barrier between the metal and tooling. This significantly reduces friction and prevents the formation of abrasive oxides. As a result, extruded tubes generally exhibit superior surface finish, improved corrosion behavior, and lower rejection rates in downstream processes like welding or bending.

Microstructure and Mechanical Uniformity

The method of deformation directly influences the grain structure of the final tube, which in turn determines its mechanical properties and service performance.

In the piercing process, the deformation relies on tangential shearing forces generated by the Mannesmann effect. This shearing action can result in non-uniform grain flow, particularly around the inner wall, and increases the likelihood of forming internal laminations or local weaknesses. Variations in roll settings, temperatures, and billet consistency can further amplify these structural inconsistencies.

Extrusion, by contrast, applies axial compressive force through a die. This mode of deformation refines the grain structure uniformly across the wall thickness, promoting enhanced ductility and strength. The result is a homogenous tube with fewer discontinuities, ideal for applications demanding high fatigue resistance or exposure to cyclic stresses. Uniform mechanical performance and reliable dimensional tolerances make extruded tubes a strong choice for petrochemical, aerospace, and nuclear industries.

Process-Induced Reliability

Each method’s process stability directly affects repeatability and quality assurance. Piercing involves multiple mechanical components — piercing plug, guide disc, and skew rolls — each introducing variability in deformation path and force distribution. Fluctuations in these parameters may cause inconsistencies in wall thickness, surface finish, or ID geometry, requiring intensive quality inspection and process correction.

Extrusion is more self-contained and typically executed in a single press stroke, allowing for tighter control of thermal and mechanical parameters. This reduces variation across production batches and simplifies the implementation of robust quality control protocols. For critical applications where traceability and consistency are essential, extrusion offers clear advantages in process reliability.

Defect Analysis: Piercing-Induced Failures

The visual and metallographic evidence of piercing-induced defects provides important insight into the limitations of this method. A typical example involves the formation of diagonal, deformation-related cracks during hot working. These flaws originate from the high shear stresses and eccentric load distribution inherent in the piercing stage.

Pic 1. The fracture surface exhibits signs of intergranular failure, characteristic of material behavior with insufficient ductility under high-temperature conditions.

Pic 2. The inclined cracks are oriented at an angle to the tube axis, which is typical of deformation-related damage caused by shear stresses.

Such cracks typically manifest at an angle to the tube axis — a hallmark of torsional deformation and shear overload. The fracture surfaces often display intergranular characteristics, suggesting brittle behavior under thermomechanical stress. These microcracks form early during deformation and can propagate through the wall, especially in sections with uneven thermal distribution or insufficient plasticity.

The presence of these defects leads to a measurable decline in mechanical strength, particularly under internal pressure or tensile stress. They compromise the sealing capability of the tube and elevate the risk of failure during subsequent forming or heat treatment. From a production standpoint, this means increased rejection rates, additional mechanical finishing, and higher cost per unit.

The root causes of such flaws include poor billet centering, asymmetric loading, inadequate heating uniformity, and process sensitivity to billet surface defects. Unlike extrusion, which removes the central zone and applies uniform compression, piercing lacks the ability to control localized shear zones effectively — making it less suitable for premium-grade applications.

Conclusion

Both piercing and extrusion hold valid positions within the spectrum of seamless tube manufacturing. However, when assessed through the lens of material quality, extrusion offers a more reliable and consistent outcome. By eliminating the billet core, managing surface friction, and promoting uniform grain structure, extrusion minimizes internal and external defects. This makes it the process of choice for high-integrity stainless steel tubing, particularly in nuclear, petrochemical, and instrumentation sectors.

Piercing remains a viable and economical option for standard tube production with moderate performance demands. Yet for engineers prioritizing defect control, corrosion resistance, and mechanical uniformity, extrusion represents a technically superior solution aligned with the increasing quality expectations of global end-users.